The construction industry is Australia's second largest employer and contributes around 9% to our overall GDP. However, it's productivity is lagging. Arka Ghosh, Digital Assets Leader argues that the Internet of Things (IoT) can change this, if the industry is willing to take up the challenge of bringing its manual processes to the online world.

There is an urgent need to integrate automation into the construction industry through the Internet of Things (IoT). Construction is a big driver for the Australian economy, with a GDP of around $360 billion as of 2022, it contributes 9% of Australia's overall GDP. It employs 1.1 million people, making it Australia's second-largest employer [1]. However, the construction industry’s productivity has been grossly underperforming in Australia. According to the Australian Government’s Commission into Productivity, the sector is prone to 'sluggish and significant wastage' [2].

Automation would significantly improve the productivity of the industry and streamline all activities in a systematic, organised manner. It would enable easier planning and monitoring, providing essential tools to on-the-ground construction workers to perform with optimum efficiency.

IoT is proposed by experts as a potential gamechanger under the umbrella of "digital solutions" that can automate the construction sector. It is predicted that the IoT will have a significant monetary impact - saving 22-29% of the total costs in construction, equating to $75-96 billion in annual benefits [3]. IoT will ensure high speed of reporting, reducing the cost of communication. It will ensure better process control and optimisation.

It is predicted that the IoT will have a monetary impact of saving 22-29% of the total costs in construction, equating to $75-96 billion in annual benefits.

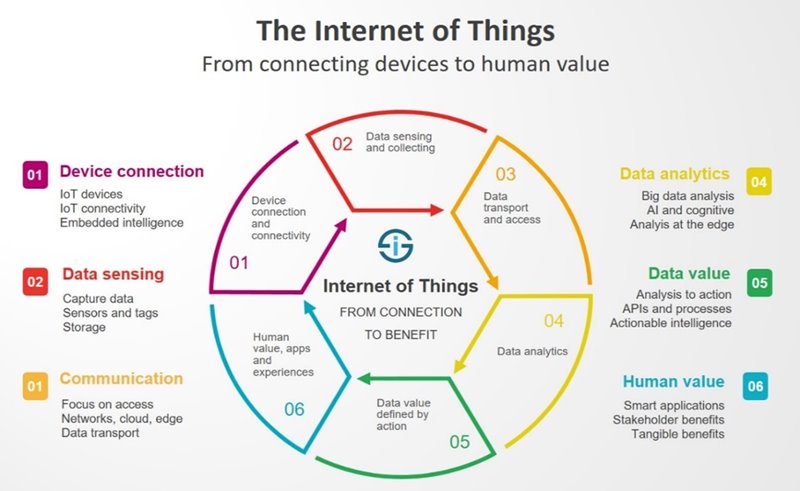

The Internet of Things redefined – from connecting devices to creating value –Source i-Scoop

Internet of Things for the construction industry

Where to start in a digital overhaul of an entire industry? Firstly, the construction industry needs to adapt and transform itself from traditional to digital to address its challenges in the Industry 4.0 age.

IoT provides exciting opportunities for the construction industry to solve its time and resource constraints and frequent defaults. Construction operations are typically spread across large areas and require remote collaboration between multiple contrasting departments and resources, creating the need for ubiquitous, rapid and automated decision-making on the worksite [4].

Considerations for future applications

| What | How | Outcome / Goal |

|---|---|---|

| High-speed reporting | Real-time available data and interconnected devices will significantly improve the speed of reporting and greatly reduce the cost of communication. | This will facilitate rapid decision-making and improved implementation of management decisions. |

| Complete process control | With real-time monitoring of essential parameters, the construction processes will be better controlled and less prone to be negatively affected by external factors. | Project managers will exercise greater process control over all the activities, and the unpredictability and disorganisation associated with the construction industry will be ameliorated. |

| The explosion of valuable data | There needs to be integrated research towards establishing datahubs to synchronise and reconcile conflicting data changes, enforce semantic consistency of information, and generate unique persistent identifiers by the registry-style data hub, which will allow the consuming application to either retrieve or assemble an integrated view. | IoT will bring about an explosion of data due to the numerous ubiquitous devices employed to measure and monitor various parameters for numerous disparate activities. It leads to important future challenges like data storage and data security. Even cloud-based solutions would prove to be inadequate to contain the enormous influx of data coming from IoT devices [5]. |

| Deep data analytics | The use of IoT in the construction industry will lead to the accumulation of intensive data about every aspect and activity involved in the project. | This will facilitate the employment of big data analytics techniques like statistics [6], data mining [7], machine learning, regression, classification, and clustering to improve the efficiency of construction processes. |

| Strict ethical and legal implications | Presently, the rules regarding data access and security are rather vague or, in some cases, non-existent in the construction industry [8]. The increasing volume of data raises important questions regarding data security, ethical and privacy violations and unauthorised access and misuse of confidential data. | Companies must develop strict data usage and IT rules and policy frameworks to protect the rights of all stakeholders, involved-from workers to clients. |

| Higher expectations | The use of IoT devices in the construction sector could lead to increased client expectations and unrealistic targets. It needs to be clear from the outset that IoT could act as a monitoring tool, not as a magic stick that can solve external problems like harsh site conditions or socio-political issues when it comes to construction projects. | The construction industry must carefully manage expectations when implementing IoT techniques. |

Interconnected technologies

Although IoT-enabling technologies have been discussed, additional sensors make up a network of interconnected things which have been widely employed in the construction industry, such as:

- Vision-based: The use of cameras for automating various project management tasks [9] and monitoring the project progress in real-time [10].

- Ranging-based: The use of ranging-based detection techniques like LiDAR (Light Detection and Ranging) and LADAR (Laser Distance and Ranging) for detecting structural faults and progress status [11].

- Location based: Leveraging local systems like Global Positioning System (GPS) [12] and Ultrawide Band (UWB) for tracking construction activities [13].

- Radio Frequency Based (RFID): RFIDs have widespread applications in the construction sector, which have been enumerated as follows:

- Logistic and supply chain management (automated construction equipment leasing/plant hire)

- Inventory management (inventory control and stock distribution)

- Quality management (embedded RFID in building elements to monitor their quality/performance parameters)

- Waste management (construction and demolition waste through Trip Ticket System)

- Workforce management (RFID ID cards monitoring attendance records and site access)

- Worker safety (RFID chips monitoring essential health diagnostics-heart rate, pulse rate and proximity to danger zones)

- Asset management (tracking of machinery and tools as well as operation stats and predictive maintenance for all equipment).

Key takeaways

The construction industry has suffered dramatically in the past due to the delayed uptake of several game-changing technologies. The Victorian state government has done credible work regarding drafting a Digital Assets strategy roadmap. Other states are slowly following suit, but there remains a growing need to translate theory into practice and identify some of the possible barriers preventing its smooth uptake in the construction industry.

Some of the key positive actions the Australian construction industry can take regarding IoT adoption are:

Incorporate interoperability and clear value propositions

A significant lack of clarity exists between the seamless coordination between various departments regarding the collection, monitoring and regulation of data along with their processing and analysis at an integrated level, to enhance decision-making and straightforward value addition. This obscurity can only be resolved through proper integrated planning before employing IoT devices/techniques. Clear guidelines, policies and benchmarking regarding IoT devices and procedures would greatly assist in clearing these murky waters.

Increased privacy and security

Numerous researchers have expressed concerns over the legality, privacy and governance of the enormous data generated, which, if misused, could prove to be immensely counterproductive to the main aims of employing IoT. Unscrupulous hackers and data thieves may maliciously corrupt stored data or use historically compiled data to further their nefarious purposes. The security protocols and access must be carefully developed and monitored to prevent this occurrence.

Updated governance structures

The construction industry has traditionally been governed by rigid and bureaucratic hierarchies resistant to change and evolution. This significantly hinders the gradual and smooth uptake of IoT techniques and processes. The only solution is to make the upper management aware of the numerous benefits of IoT, especially in an economic context, so that change is affected from a top-down flow, making it more effective and integrated, rather than a bottom-up approach which usually results in point-solutions as observed from the literature review.

Business planning

Effective business plans must be formulated incorporating IoT techniques. A practical benefit-cost analysis proves necessary evidence before the uptake of any new technique in a project. Failure to plan the uptake in a systematic process would significantly hinder the successful adoption of IoT in construction projects.

References

[1] Australian Bureau of Statistics 2021, 6291.0.55.001 - EQ06 - Employed persons by Industry group of main job (ANZSIC), Sex, State and Territory, November 1984 onwards, viewed 1 August 2021, https://www.abs.gov.au/statistics/labour/employment-and-unemployment/labour-force-australia-detailed/may-2021

[2] East, CS 2013, 'This publication is available from the Productivity Commission website at www. pc. gov. au. If you require part or all of this publication in a different format, please contact Media and Publications.

[3] Australia's IoT Opportunity: Driving Future Growth An ACS Report, 2018, ACS.

[4] Louis, J & Dunston, PS 2018, 'Integrating IoT into operational workflows for real-time and automated decision-making in repetitive construction operations', Automation in Construction, vol. 94, pp. 317-27.

[5] Tang, S, Shelden, DR, Eastman, CM, Pishdad-Bozorgi, P & Gao, X 2019, 'A review of building information modeling (BIM) and the internet of things (IoT) devices integration: Present status and future trends', Automation in Construction, vol. 101, pp. 127-39.

[6] Huang, Y & Beck, JL 2013, 'Novel sparse Bayesian learning for structural health monitoring using incomplete modal data', in Computing in Civil Engineering (2013), pp. 121-8.

[7] Wu, X, Zhu, X, Wu, G-Q & Ding, W 2014, 'Data mining with big data, IEEE transactions on knowledge and data engineering, vol. 26, no. 1, pp. 97-107.

[8] Oesterreich, TD & Teuteberg, F 2016, 'Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry, Computers in Industry, vol. 83, pp. 121-39.

[9] Brilakis, I & Soibelman, L 2005, 'Content-based search engines for construction image databases', Automation in construction, vol. 14, no. 4, pp. 537-50.

[10] Golparvar-Fard, M, Pena-Mora, F & Savarese, S 2012, 'Automated progress monitoring using unordered daily construction photographs and IFC-based building information models, Journal of Computing in Civil Engineering, vol. 29, no. 1, p. 04014025.

[11] Turkan, Y, Bosche, F, Haas, CT & Haas, R 2012, 'Automated progress tracking using 4D schedule and 3D sensing technologies, Automation in construction, vol. 22, pp. 414-21.

[12] Lee, SS, Park, S-i & Seo, J 2018, 'Utilisation analysis methodology for fleet telematics of heavy earthwork equipment, Automation in construction, vol. 92, pp. 59-67.

[13] Shahi, A, West, JS & Haas, CT 2013, 'Onsite 3D marking for construction activity tracking', Automation in construction, vol. 30, pp. 136-43.

New Zealand

New Zealand

Australia

Australia

Singapore

Singapore